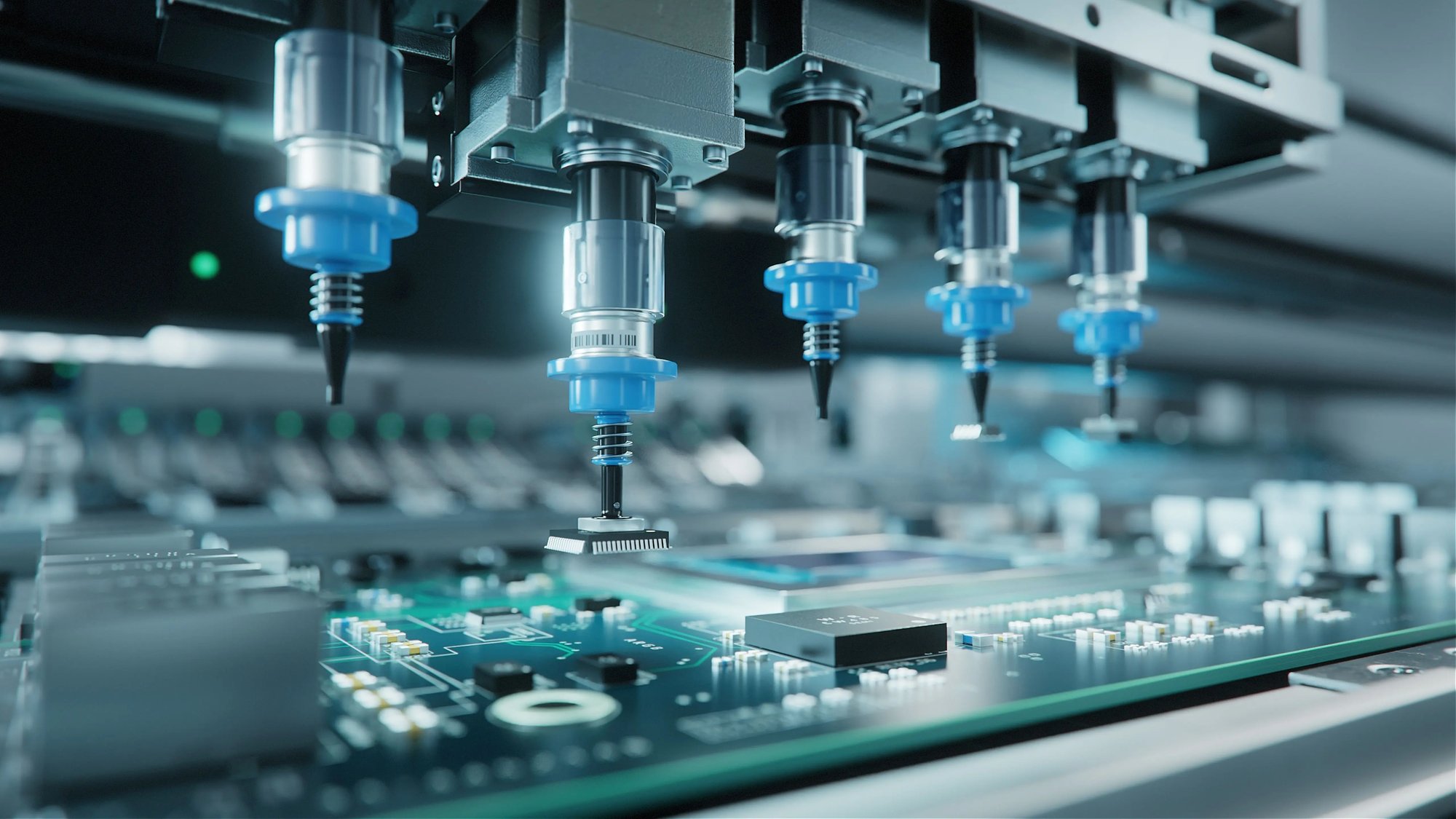

Enhancing Machine Tool Simulations with RecurDyn offers significant benefits across a broad spectrum of precision manufacturing equipment, including engineers developing machine tools, coordinate measuring machines, Die Bonders, and SMT (Surface Mount Technology) machines. The inclusion of the capability to model structural feedback from dynamic positioning on secondary axes enriches the simulation environment, catering to a wider range of precision equipment developers:

Realistic Modeling:

RecurDyn's detailed modeling capabilities extend beyond SMT and Die Bonders to include machine tools and coordinate measuring machines, accounting for flexibility and dynamic effects. This results in accurate simulations of mechanical interactions and electronic component integrations across all these equipment types.Analysis of Flexibility Influence:

The precision required in component placement and measurement in Die Bonders and coordinate measuring machines alike benefits from the inclusion of flexible bodies in simulations. RecurDyn's analysis can lead to significant design optimizations by examining the impact of flexibility on the accuracy and reliability of equipment movements.

Efficient Problem Resolution:

Early identification of potential issues such as vibrations, unwanted movements, or part conflicts is crucial not just for SMT and Die Bonders but also for machine tools and measuring machines, allowing for cost-effective solutions before moving to prototype stages.

Optimization of Equipment Performance:

The virtual environment provided by RecurDyn enables engineers across these disciplines to test configurations and settings, optimizing for movement precision, efficiency improvements, and wear reduction.

Reduction in Development Time and Costs:

The comprehensive testing and analysis capabilities reduce the reliance on physical prototypes, speeding up the development process and cutting associated costs for developers of all specified equipment types.

Advanced Analysis Capabilities:

With its advanced features for studying multibody dynamics, stiffness, damping, and contact forces, RecurDyn is indispensable for ensuring that machine tools, measuring machines, Die Bonders, and SMT machines perform reliably under a variety of operational conditions.

User-friendliness and Integration:

RecurDyn's intuitive interface and seamless integration into development workflows enhance collaboration and facilitate the use of simulation results in design decisions, beneficial for teams across all mentioned equipment development.

Modeling Structural Feedback:

The ability to model structural feedback on secondary axes is particularly vital not just for SMT and Die Bonders but also for machine tools and measuring machines, where precision is paramount. This capability allows for the prediction and analysis of stability and accuracy impacts, leading to design adjustments that minimize unwanted vibrations or movements and enhance overall equipment performance.

Achieve Unmatched Precision and Efficiency in Component Placement

FunctionBay GmbH offers deep expertise in the precision engineering of SMT machines. By understanding the intricate dynamics of placement heads and nozzles, our team ensures the highest precision and efficiency in component placement. Our approach reduces misalignment and increases reliability, crucial for high-speed assembly processes, enabling you to optimize machine performance and accuracy.

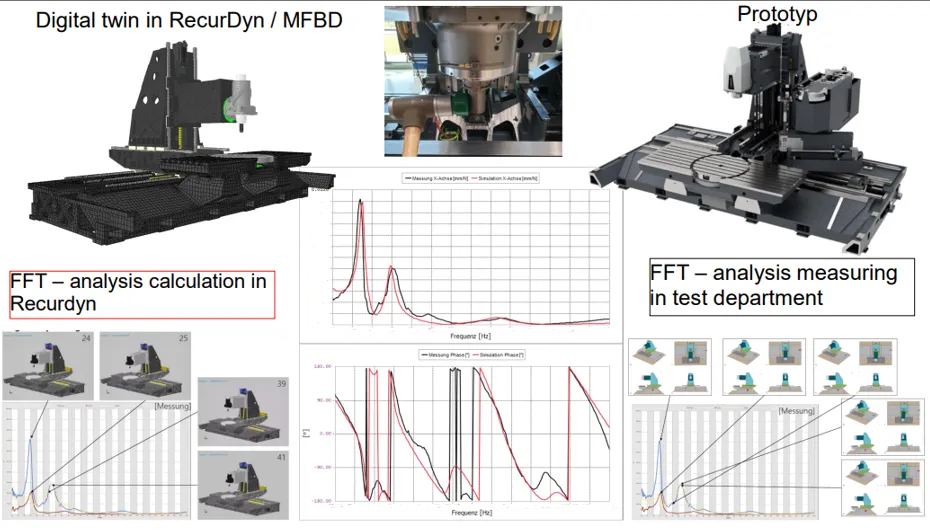

Empower your engineering with the latest in simulation technology. We proudly introduce our dynamic twin model, crafted using the sophisticated RecurDyn software in conjunction with FBG.Machinetool. This cutting-edge combination brings to life the dynamic simulation of machine tools, offering an unparalleled level of accuracy and realism.

Designed to mirror the real-world performance of machine tools, our model provides an in-depth understanding of machine behavior under various operational scenarios. From intricate component interactions to comprehensive system responses, our dynamic twin model offers a detailed insight into every aspect of machine tool performance.

Discover the next level of machine tool simulation and elevate your engineering projects to new heights.

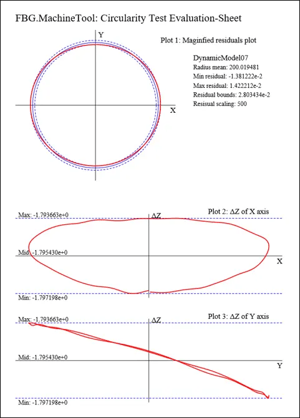

Discover unparalleled accuracy in machine tool behavior with our cutting-edge simulations. Our Circularity Test delves deep into the fidelity of circular shapes, comparing simulated paths with actual measurements for unmatched precision. We emphasize crucial quadrant transitions, addressing challenges such as dynamic forces on ball screw drives. Our simulations reveal key insights, identifying discrepancies and potential improvements, ensuring real-world scenario mimicry. Concluding that our methodology accurately replicates real systems, this tool is essential for the flexible multibody simulation of machine tools. Step into the future of precision engineering with our innovative simulation solutions.

Experience precision engineering like never before – your key to advanced machine tool simulations.